Clock Striking Mechanism

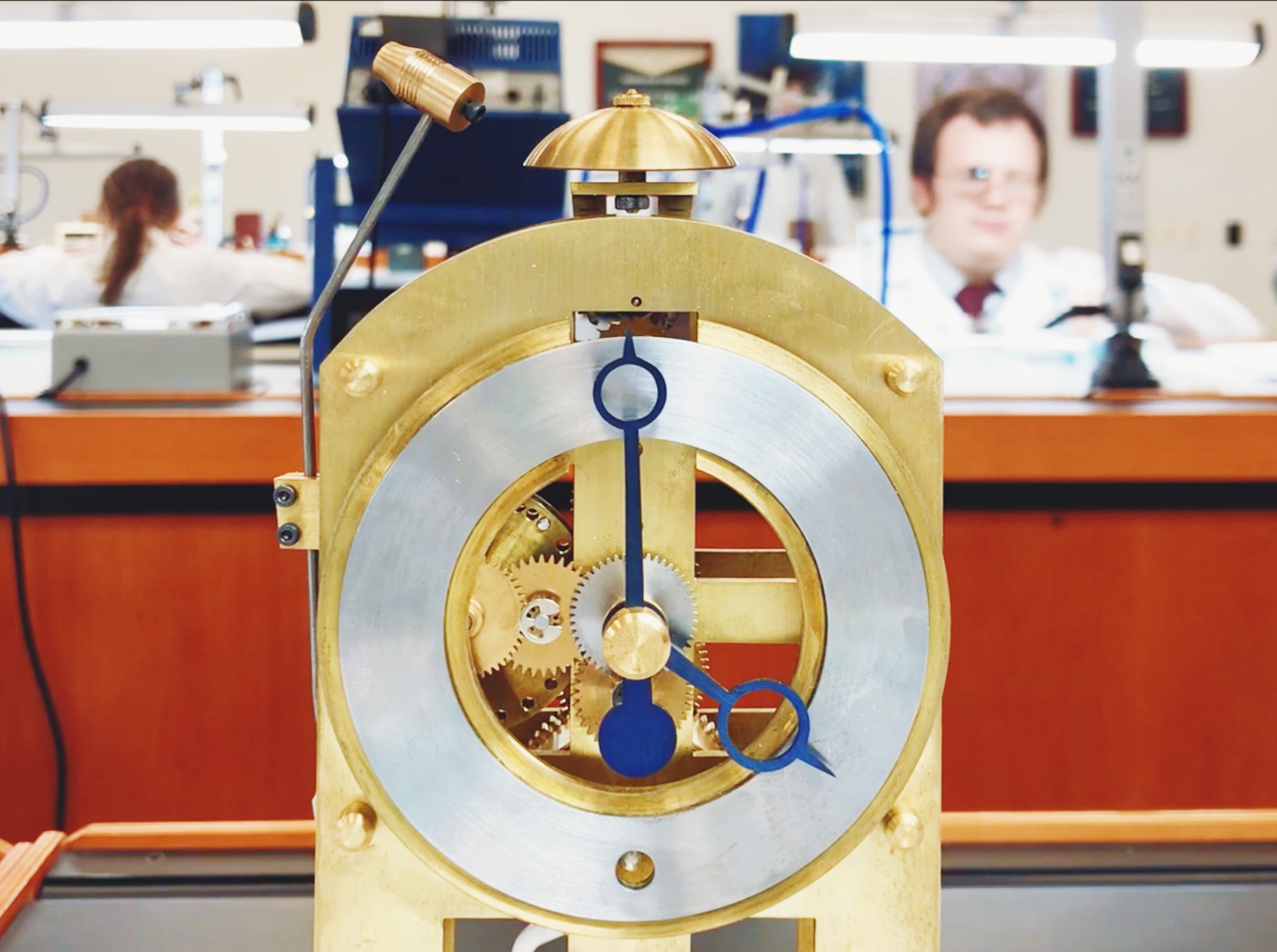

The school clock striking mechanism is a pretty simple affair, all things considered.

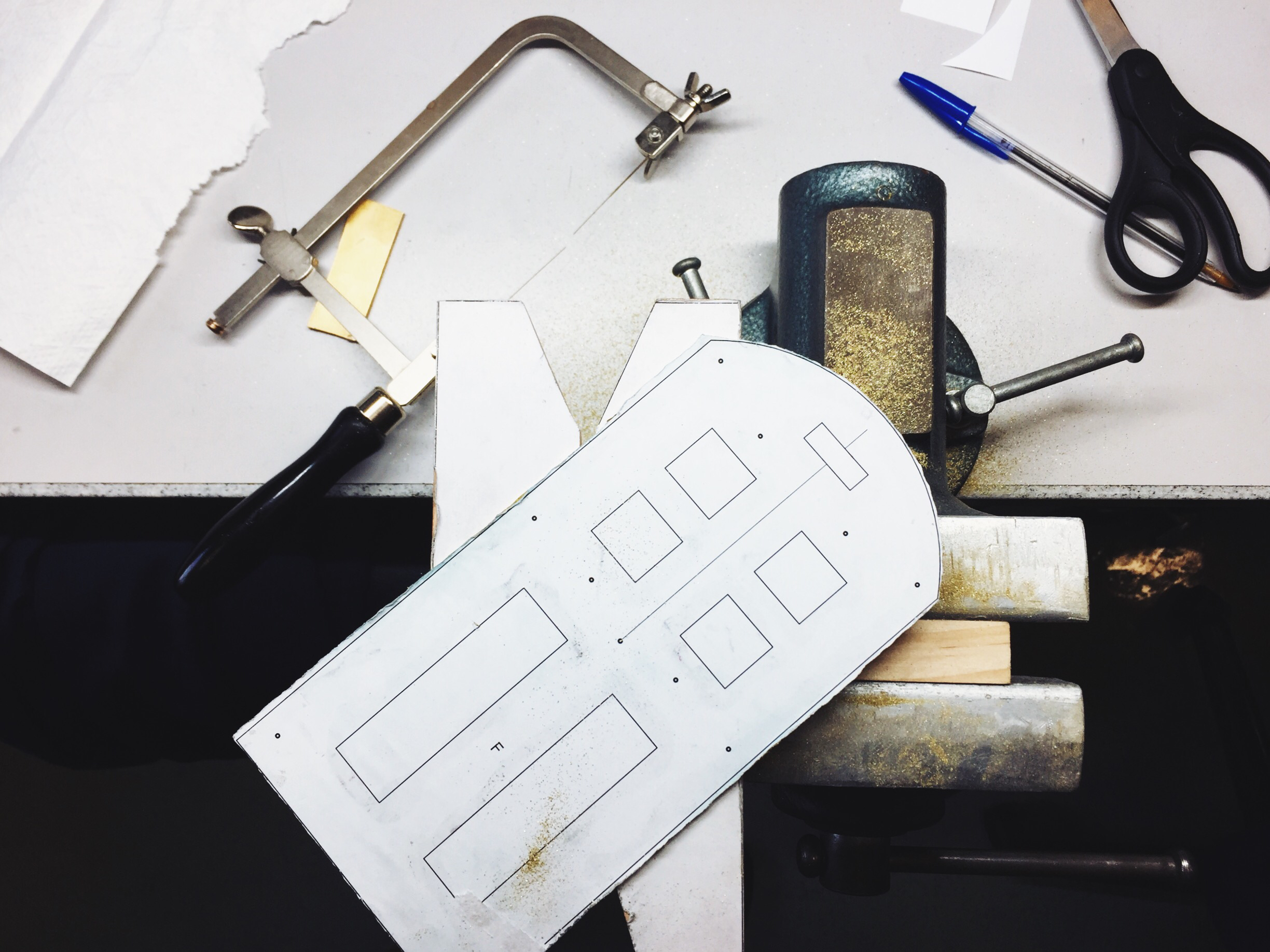

Above are all the parts that make it work. The heart of the mechanism is the count wheel, which is geared to the hour hand, and has 24 holes for pins that will allow it to ring at 30 minute intervals over a 12-hour period. Eagle-eyed readers will notice a 25th hole, which will serve a different function later.

Power is taken off the minute wheel by a secondary minute wheel, which drives a second hour wheel. The hour wheel is attached to the count wheel arbor with a screw, allowing synchronization adjustment after assembly. Hardened steel pins in the count wheel rotate counterclockwise, pushing down on a wedge on the hammer, lifting it to charge the mechanism. As the wedge slips off the pin, the hammer (assisted by a spring) falls and rings the bell. Existing clock pillars are used as the hammer's pivot and stop—as it falls, the hammer hits the upper pillar and flexes to hit the bell, but recoils to allow it to ring.

The bell is suspended on a shouldered pencil eraser (which turns beautifully in the lathe, apparently) that sits around a threaded post which attaches to the bridge, itself mounted over the pallet bridge. While this allows the bell to be on top of the clock, it unfortunately doesn't allow for enough clearance for the school-supplied bell jar; a better design would hang the bell and hammer inside the clock's empty lower half to keep everything self-contained and remove the need for the spring.

Apart from the wheels and the spring, every part of this mechanism was made from scrap and was machined relationally to fit. Since this is intended to be repeatable, we'll be making better blueprints so that any future student can attempt to craft the mechanism for themselves.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.