Lightning Project: Gridiron Pendulum

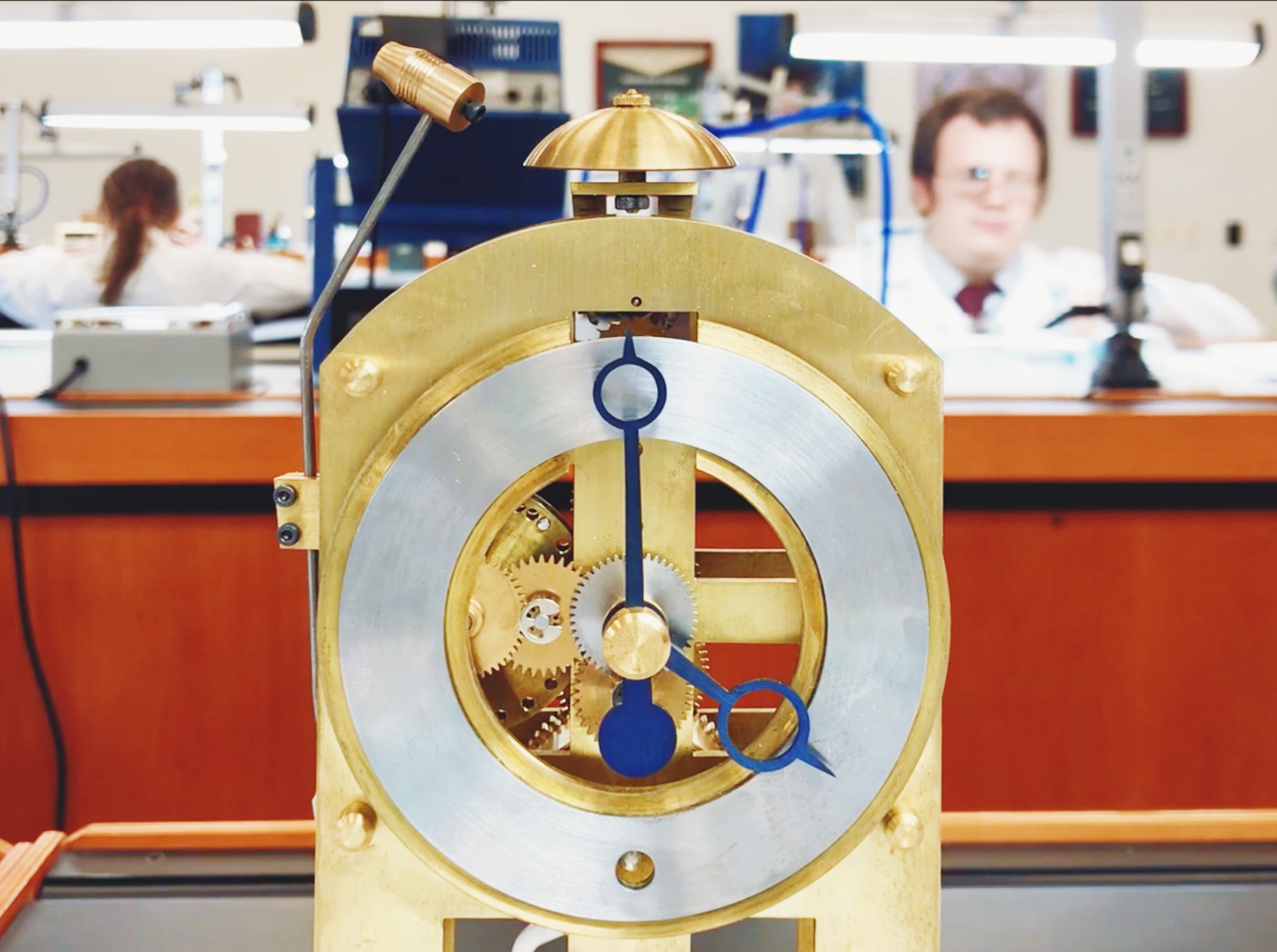

To cap off the 2017 school year, Justin and I decided to make a prototype temperature-compensating gridiron pendulum, start to finish in a single day.

The gridiron pendulum is similar to the bimetallic split balance wheel, in that it uses different metals to compensate for temperature errors at the oscillator. Unlike the bimetallic balance wheel, the making of a gridiron pendulum has been thoroughly detailed and documented—and is immeasurably easier to do.

A pendulum's period, or rate of oscillation, is tied to the length of its center of mass, not its weight. Because most metals expand in heat, the pendulum rod and bob will get longer, slowing the clock. The gridiron pendulum takes advantage of metal's natural thermal expansion and uses opposing expanding rods to compensate for any change in dimensions.

Gridiron pendulums are traditionally made of brass and either steel or nickel. Nickel has a higher coefficient of thermal expansion, so it's able to compensate with fewer back-and-forths. We found a stash of thin nickel rods in a drawer, so it seemed as good idea as any to make them into a gridiron.

The ugly pendulum bob is just a test piece to get the weight right.

Temperature compensation is achieved by using the different metals to alternately push up and down on each other. In this design, the outer nickel rods push down on a crosspiece that supports the inner brass bars and lets the middle nickel rod pass through. Those brass bars push up on another cross piece, which supports the center rod, holding the pendulum bob (the outer brass bars just support a locator for the center rod). Together, the opposing expansions should keep the weight of the bob in the same place... Theoretically.

The gridiron pendulum was innovated by master chronometer maker John Harrison, and in the right hands, it works wonderfully. In reality, it's tricky to get perfect, especially when the quality of the brass and nickel is unknown.

For our purposes, the temperature compensation is actually irrelevant, since the clock lives in a thermally-controlled environment, and doesn't need it—but it's a fun project and worth trying anyway. What the clock really needs is barometric compensation, but that's a whole other can of worms!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.