Experiment: Bell-Making

The striking mechanism on my school clock would be useless without something to actually chime, so I had to make a bell.

Many high-quality clocks actually use a sort of wire gong in place of a bell, but that requires a level of expertise that I simply didn't have time to perfect in the span of a week. Besides, a bell on the top of the clock is classic and cute.

A significant source of inspiration for this project was a tool called a "dapping block" that I saw around the classroom. It resembles a series of ever smaller trailer hitches and a steel block that fits them perfectly. While it has a wide variety of uses, my first impression was that it would make a wonderful stamping kit to form a bell, and indeed it does.

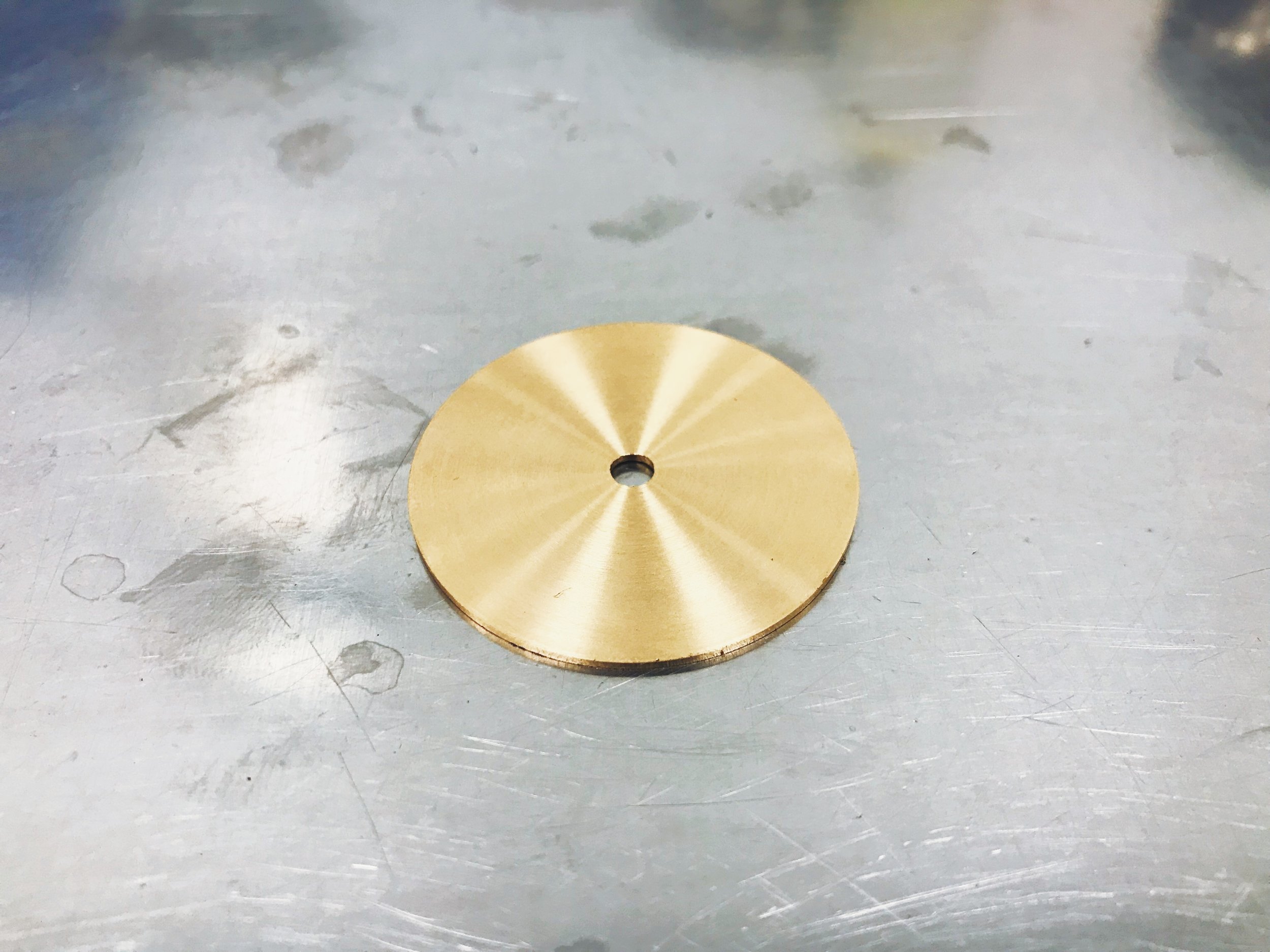

Herman, our principal, owns the dapping set and suggested that I use a piece of brass about 1 mm thick and "about the diameter of a 6497 movement case," which works out to roughly 40 mm. The scrap that I parted off to use for the bell had a hole drilled through the middle, which incidentally made the entire process easier, though at first we didn't know whether or not it would work.

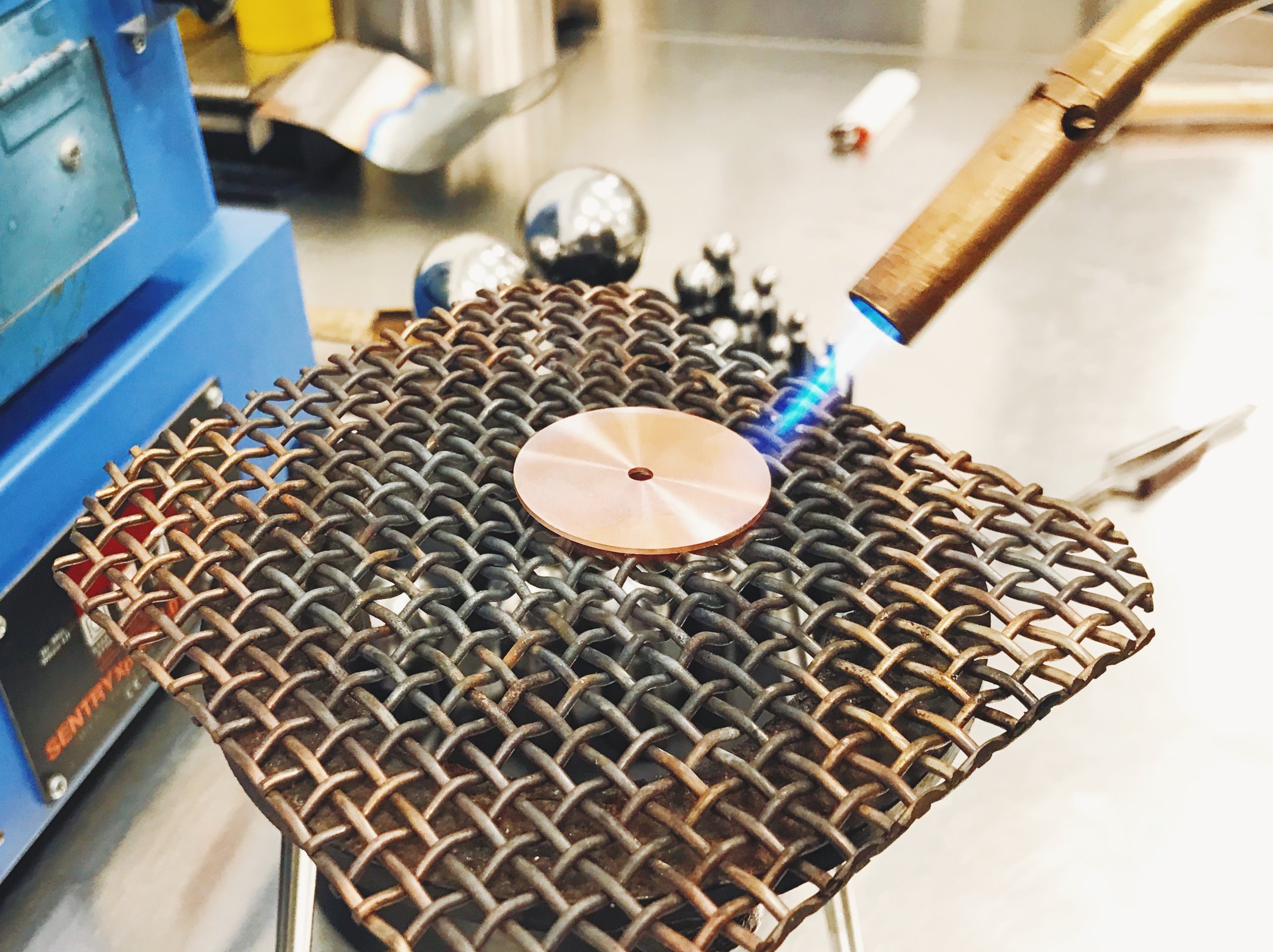

Forming the bell is pretty easy. Heat up the brass, place it in the die, align the ball stamp with the middle and hit the back end of the stamp with a hammer. Repeat until you have a bell.

The heat not only makes the metal softer and more malleable, but it equalizes stresses in the workpiece, helping it to resist cracks and tears. My best results came with the brass heated almost to a dull red, so it was pretty hot.

Forming the metal takes some pretty good whacks with a decently heavy hammer.

That's starting to look like something!

After several rounds of heating and hammering, the brass is fully formed to the shapes of the die and the stamp. To increase the curvature, it could be transferred to a smaller die, but this was good enough for me.

The bell has a bit of a double resonance, but it's good enough for a first attempt! A thinner piece buckled as I stamped it and generally sounded like cheap tin. It'll take some experimentation to really get the tuning dialed in.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.