Finishing: Perlage

Perlage is one of the two machine finishes that I'll be applying to my school watch, though it'll largely be out of sight.

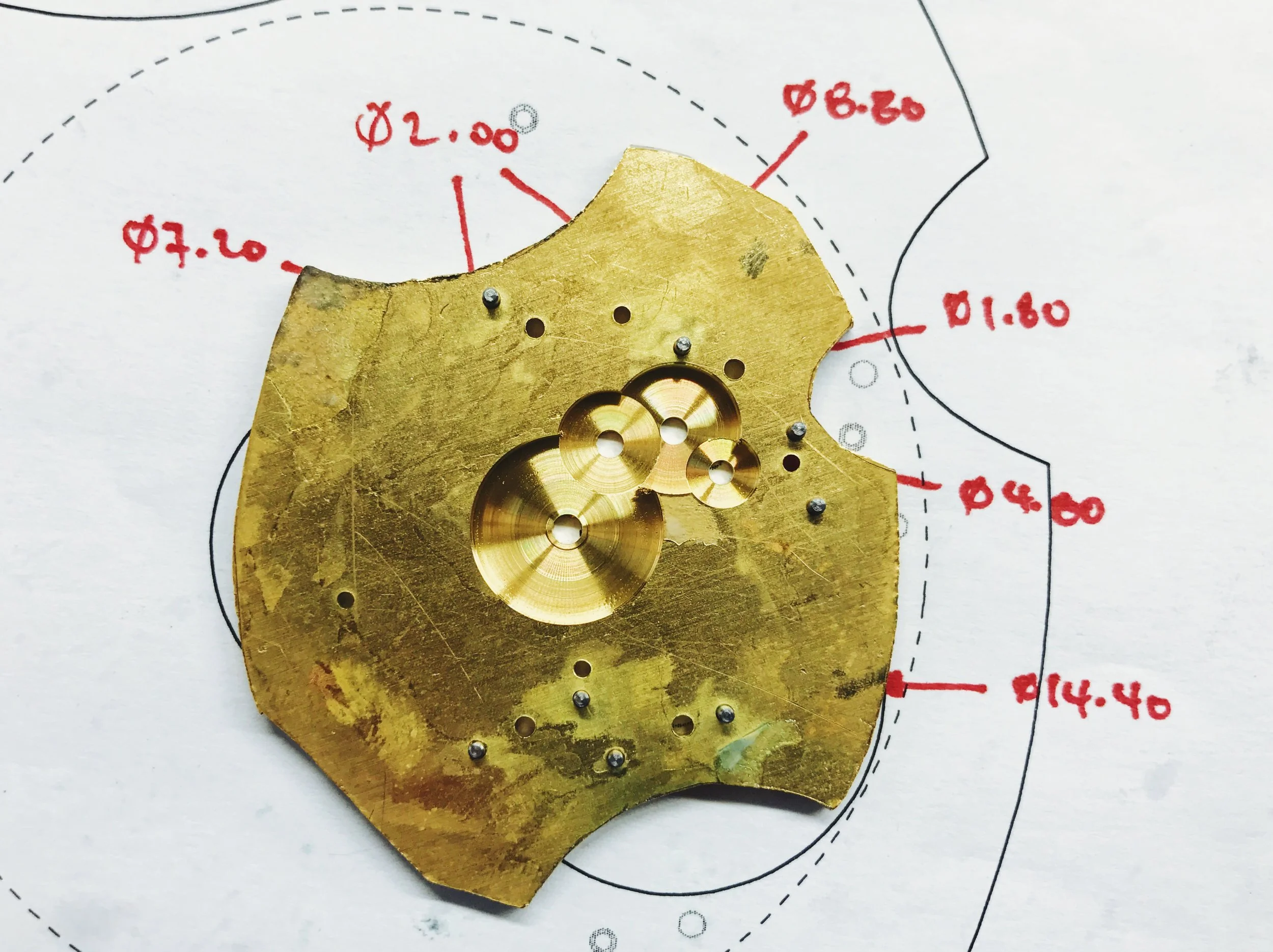

Traditionally, perlaged surfaces are on the bottom layer of a watch movement—that is, on the mainplate or other lower bridges—so that's where I'll be applying the finish as well.

The finish is nothing more than a series of overlapping concentric circles of overlapping circles. It's a bit "busy" compared to the other watchmaking finishes, which may explain why it's rarely used on the most visible surfaces.

We don't have a dedicated machine for perlage, since it's pretty simple to set up on a drill press. The mainplate (or whichever component will be finished) fits on a jig that has multiple pivot sizes, allowing you to rotate the piece concentrically. An abrasive rod is fitted into a mandrel in the drill chuck, and the circles are formed by drawing the rod down onto the workpiece.

Thanks to my classmate Eric for tolerating me shooting this, the following GIF and the header image while he perlaged his mainplate.

Since neither the jig nor the drill press have the ability to index (rotate in equal and even amounts), it's up to the operator to space the circles properly. The tightness or looseness of the pattern is up to the operator, though overlapping the circles by about 1/3 seems to be a standard distribution in the industry.

Not only do the circles have to be spaced around the circumference, but the concentric rings have to be spaced by rotating the drill press on its arbor as well. It takes practice to get all the spacings correctly, but once it's mastered, the process is pretty quick.

Next up, Côtes de Genève on the bridges!

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.