Lathe: Precision

As the difficulty on our lathe projects increases, the allowed tolerance decreases. Today we hit +/- 0.00 mm.

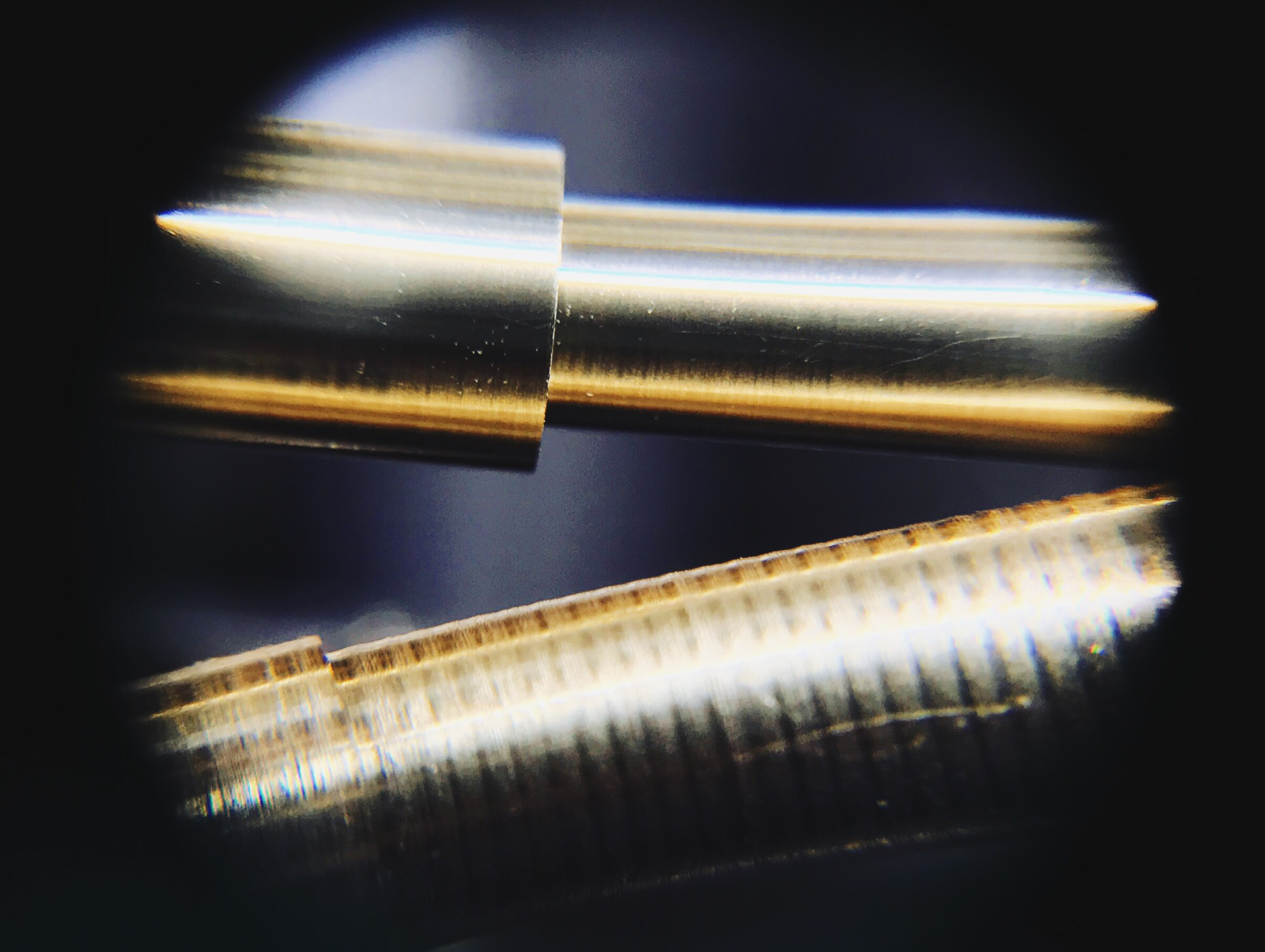

We're continuing to work on the clock, this time making pillars for the dial. These pillars are just under 10 mm long, but they're introducing a whole new level of complexity, since they must be friction-fit into the plates.

Friction fitting means that friction is the only force keeping an item in a hole where it belongs. Jewels are friction fit, which is why they have to be pressed in and out with a tool. When it comes to friction fitting, the dimensions must be exact. 1/100th of a millimeter too large or too small, and the fit is ruined.

0.01 mm can be hard to visualize. The go-to reference is a human hair—we're talking about a tenth the width of a hair here. 0.01 mm is also equal to 10 μm (micrometers), though watchmakers speak in millimeters, so it's a bit of a moot point.

Regardless of how you visualize it, 0.01 mm is small. It's almost imperceptible, even with our loupe. It's even within the margin of error of our measuring tools, so we have to make our own that can be even more precise. How? It's deceptively simple.

To find the diameter of a hole, you just have to find an object that will fit perfectly inside of it. On the lathe, we can make cylinders of any dimension. With a rough estimate of our target size, we start turning down smaller and smaller by the hundredth until... presto, the object fits.

Since friction fits have to be tight, we take a measurement off of the test pillar and add 0.01 mm to it. If we were working with steel, it would be a different procedure, but brass is soft, so the 0.01 mm allows for both objects to comfortably deform.

As with everything in watchmaking, lathe work demands great care. Zero-tolerance measurements, though, force you to be truly careful. My cutter looks rough and gross, but its edge cuts well enough, and the lathe is precise to about 0.005 mm—more than good enough for this operation.

It's a slow process. That said, less than two months into the program, and we're already finding that such feats are possible. It's a great feeling.

Watchmaking student at the Lititz Watch Technicum, formerly a radio and TV newswriter in Chicago.